Our history began in the late 1800's

Samuel Hadlock helped develop a site in Port Hadlock, Washington, to be known as the Washington Mill Company. William J. Adams, who was the grandfather of Ansel Adams, owned and operated the company. The present site of the former mill is the Wooden Boat School on S. Water Street, Port Hadlock.

1907

The Washington Mill Company closed, laying off numerous workers as a result of the proposed railroad for the region not being built, and was instead built on the east side of Puget Sound.

1909

Hope beamed when Charles H. Adams began construction on the Classen Chemical Company’s Alcohol Plant. The Washington Mill Company was able to reopen the mill and was the supplier for the sawdust and raw material needed to distill the alcohol.

1910

The Old Alcohol Plant building was fully constructed and originally owned and operated by Charles H. Adams, father of the famous photographer Ansel Adams.

1911

The Alcohol Plant opened in June 1911. Based on the works of Louis Pasteur, they processed alcohol from sawdust using the Berigus Process.

1911-1913

The Alcohol Plant shipped all of its product to San Francisco and early on ran into financial problems. With the heavy competition for alcohol product in 1913, Western Distilleries (C&H Sugar) bought up all the available stock options, taking control of the company. This caused a significant loss of capital resulting in The Alcohol Plant closing forever in 1913.

1913-1978

For decades the Alcohol Plant stood vacant and fell into disrepair. In 1948 Ansel Adams and his son Michael visited the property to decide what to do with it. It would be another 30 years before an investor would acquire the Old Alcohol Plant with a vision.

1978

Ray Hansen set sights on the building shell and the potential it presented. Purchasing it in April of 1979, and investing nine years and over $4 million, Ray and his wife Jeanne created a hotel and resort called the Inn at Port Hadlock.

1996

In May of 1996, John Ray Hansen sold the property to Paul Christensen of Realvest Corporation of Vancouver, WA. Paul’s dream was to create the Inn at Port Hadlock.

2006

Paul’s dream to create the Inn at Port Hadlock came true, the Inn at Port Hadlock opened.

2011

After several changes in ownership, government officials closed the doors on the Inn at Port Hadlock in 2011 due to taxes owed.

2014

A small group of local philanthropists saw potential in the property, later purchased by the current owners, Inn Properties, LLC in December of 2014.

2016

After much renovation to bring life back to the Hotel, it opened again on July 1, 2016, with a mission in mind and a new, old name.

The New Ownership

Bayside Housing & Services is a non-profit dedicated to strengthen community through housing, advocacy, and human services supporting social and economic independence.

The Tower Building

The Tower Building of the hotel provides temporary housing to community members in need as they improve their quality of life, and transition into permanent living situations. All the current owners are involved with Bayside’s mission and are committed to supporting those in need. As guests of the Old Alcohol Plant Hotel and Restaurant, you are assisting with this mission. We appreciate your support.

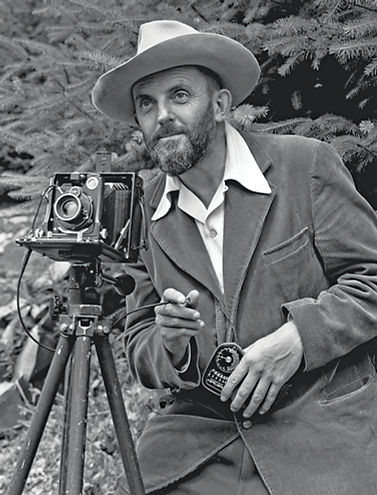

Our Tribute to the Adams Family

We have dedicated a wall to the works of Ansel Adams. The walls of this sturdy hotel will provide lodging for community members in need, create jobs to enhance our economy, and provide a beautiful waterfront location for events and classes.